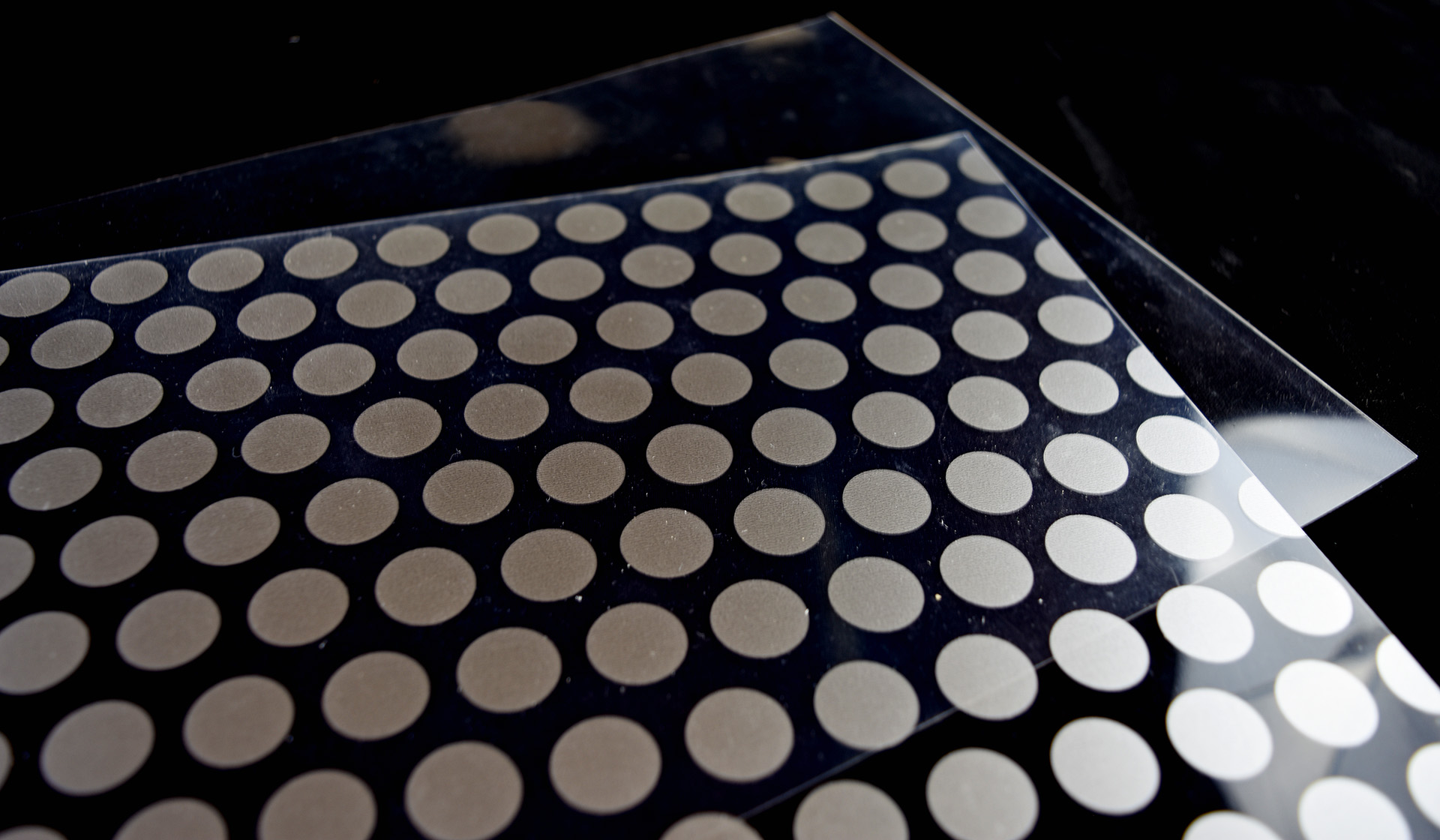

Type 4A – ETFE Waterproof Foil/Film

Main Benefits:

Additional Information:

What Is ETFE (Foil/Film):

Ethylene Tetrafluoroethylene (ETFE) is a fluorine-based plastic polymer that offers a creative and lightweight alternative to glass. Developed over 40 years ago, ETFE has a similar light transmission to glass, but at just 1% of the weight. With a lifespan of over 30 years and excellent weathering properties, ETFE film is an excellent choice in a variety of climates

See structurflex.com website for our numerous canopy projects utilizing this material.