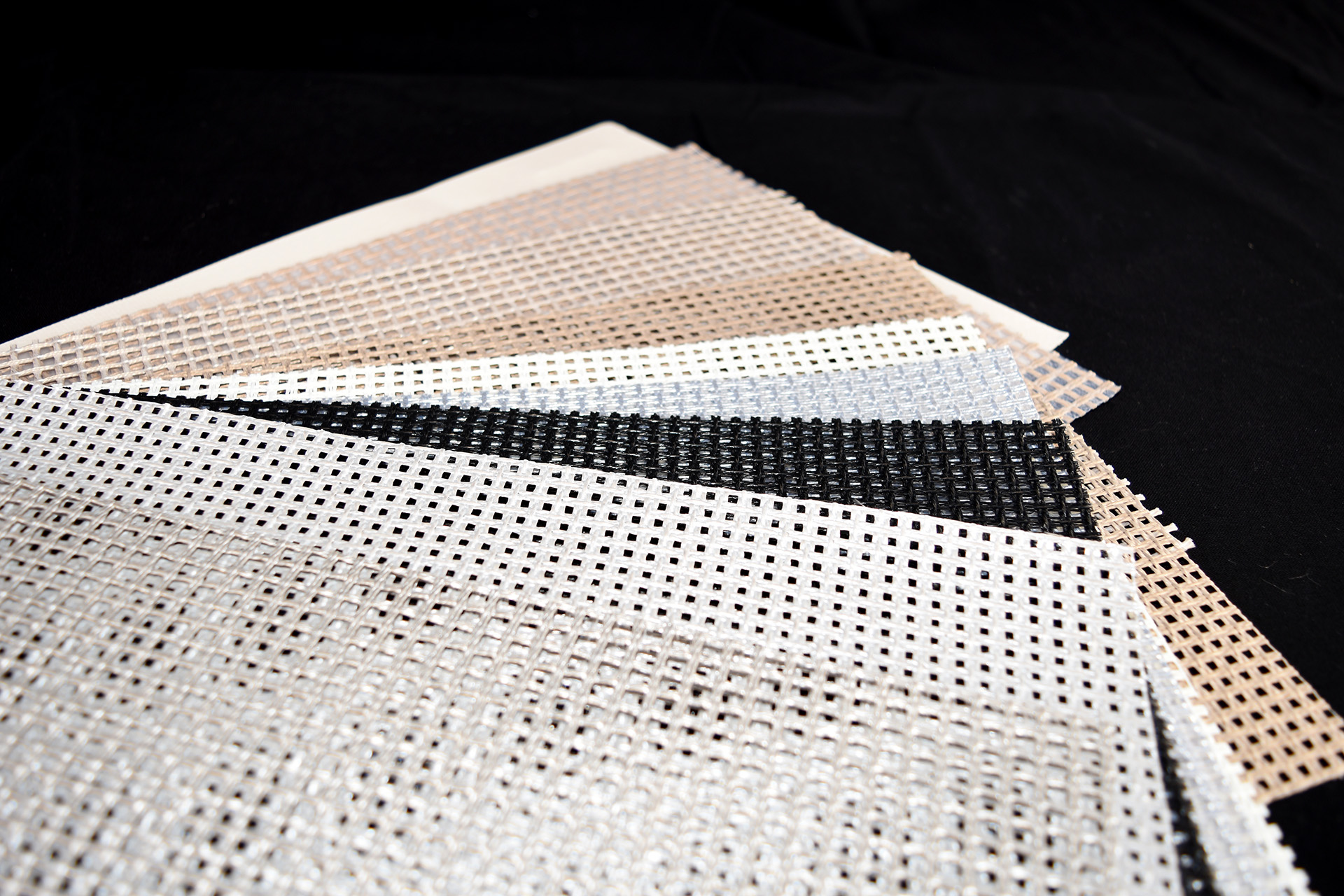

Type 2A – PTFE Fiberglass Ventilated Mesh

Main Benefits:

Additional Information:

What is PTFE Fiberglass Mesh:

Polytetrafluoroethylene (PTFE) coated fiberglass ventilated fabric mesh is the most durable fabric on the market. PTFE coated fiberglass provides uncompromised and unequaled beauty, longevity, and functionality. PTFE was developed in 1938 and has been used in building applications since the 1970s. PTFE coating is very slick, and nothing sticks to the surface making an ideal surface that is self-cleaning with rainwater.

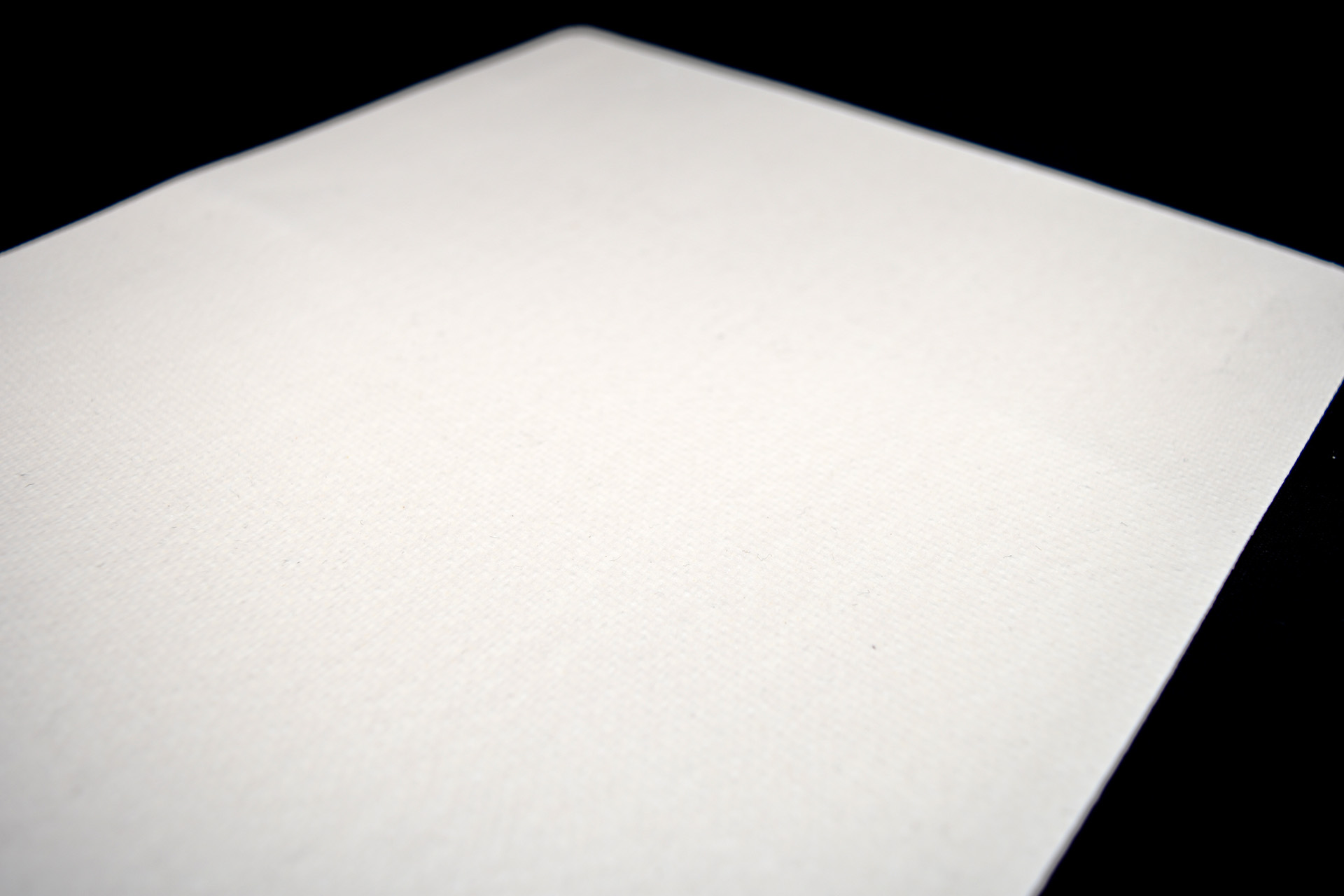

Type 2B – PTFE Fiberglass Waterproof Membrane

Main Benefits:

Additional Information:

What is PTFE Fiberglass Membrane:

Polytetrafluoroethylene (PTFE) coated fiberglass non-ventilated fabric is a membrane and the most durable fabric on the market. PTFE coated fiberglass provides uncompromised and unequaled beauty, longevity, and functionality. PTFE was developed in 1938 and has been used in building applications since the 1970s. PTFE coating is very slick, and nothing sticks to the surface making an ideal surface that is self-cleaning with rainwater.

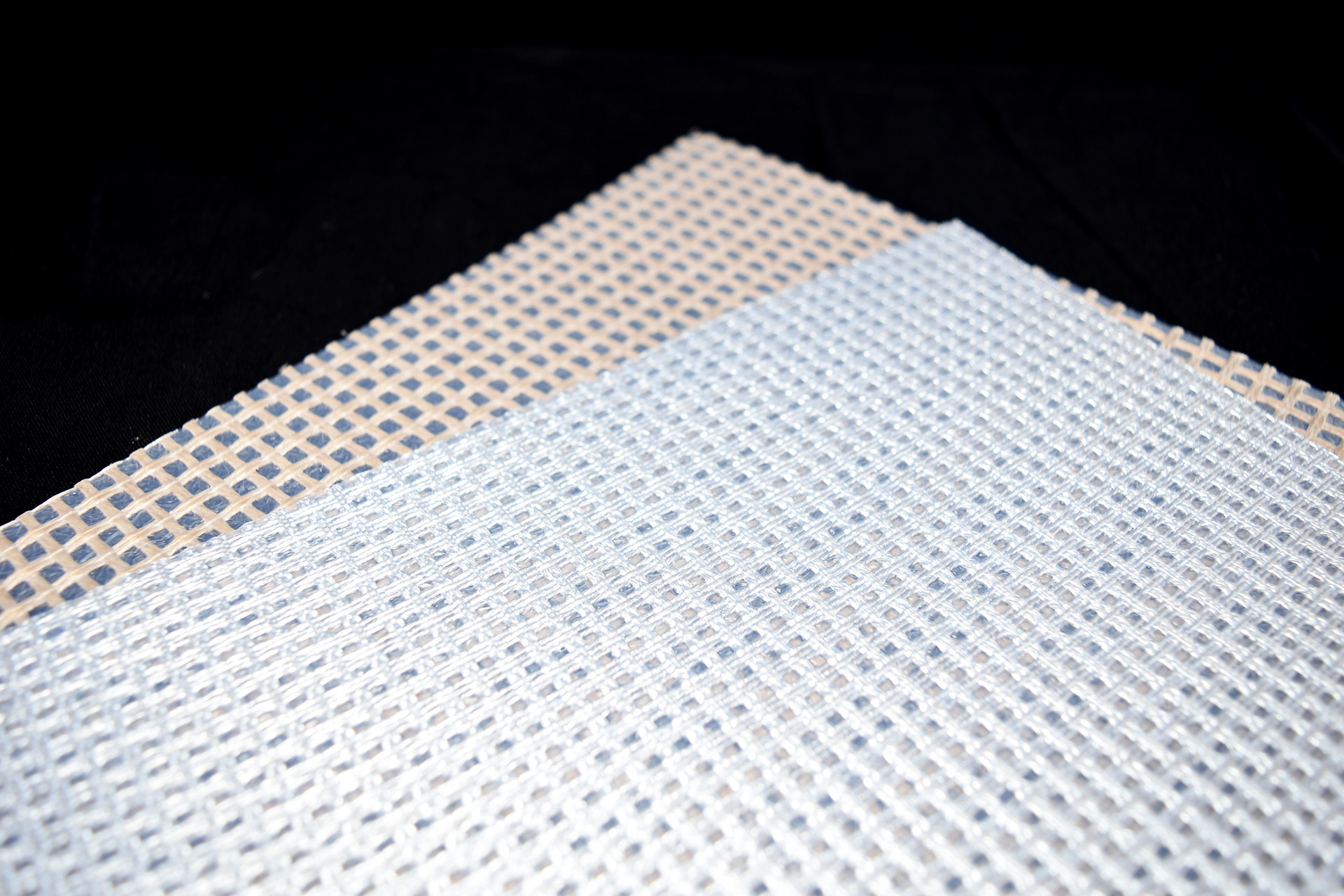

Type 2C – Laminated PTFE Fiberglass Waterproof Membrane

Main Benefits:

Additional Information:

What is Laminated PTFE Fiberglass Membrane:

Polytetrafluoroethylene (PTFE) coated fiberglass mesh fabric with an added waterproof clear laminated film creating a very unique, highly translucent membrane that is extremely durable.

See structurflex.com website for our numerous canopy projects utilizing this material.